In core industries such as silicone processing, electronic manufacturing, and textile coating, catalyst performance directly determines product curing efficiency, finished product quality, and application stability. A high-efficiency, stable catalyst not only boosts production efficiency but also endows products with superior core properties like temperature resistance and anti-yellowing, serving as a key factor for enterprises to enhance competitiveness.

The Karstedt platinum catalyst launched by Betely addresses industry pain points precisely with its core advantages of high activity and stability, making it a reliable choice in the silicone application field. When evaluating the cost of platinum catalyst, consider not only the initial price but also its longevity and efficiency.

| BETELY | Karstedt's Catalyst |

| CSAT-F50050 (Code: 17071101) | Adopts a new eco-friendly formula design, suitable for scenarios such as various electrical encapsulation and composite material products |

Part.01 | Product Highlights

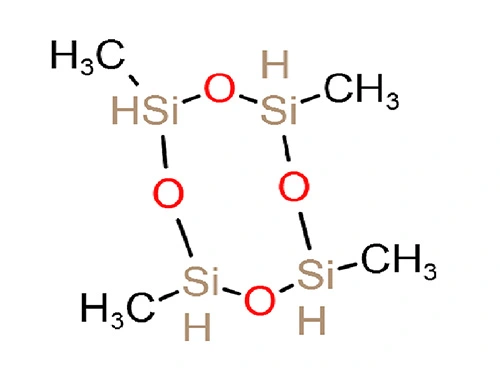

Betely Karstedt platinum catalyst is a high-efficiency catalytic product specifically designed for the addition reaction between ≡Si-Vi and ≡Si-H. It combines three core characteristics: strong activity, excellent stability, and high toxicity resistance, ensuring product quality throughout the entire process from production to application.

(Reaction principle-related descriptions: Addition Curing; Addition of H-siloxanes to C=C double bonds; Uncured state → Elastic state; Chemical structural formula: Me₃Si-Si(Me)₂-Si(Me)₃ and other related structural diagrams)

Karstedt's catalyst is a platinum catalyst with high activity and catalytic efficiency. It can efficiently catalyze the addition reaction between ≡Si-Vi and ≡Si-H without generating side reactions. Meanwhile, the product also features good stability and strong toxicity resistance, which can effectively prevent the precipitation of platinum black during product storage and use, and mitigate the adverse effects of nitrogen-containing, sulfur-containing, and other substances.

Part.02 | Core Technical Data of the Product

| Item | Specification |

| Appearance | Transparent and clear liquid, colorless and odorless |

| Active Ingredient | 100% |

| Pt Content | 200-200000 ppm |

| Specific Gravity (20℃) | Approximately 0.98 |

| Flash Point | >100℃ |

| Compatibility | Easily soluble in solvents such as toluene, 120# gasoline, and methyl ethyl ketone (MEK) |

| Storage Shelf Life | 12 months (stored in a dark place at 0-20℃) |

Part.03 | Core Advantages of the Product

High Catalytic Efficiency & Fast Curing Speed: Characterized by tc90 vulcanization time, under the same test conditions, the curing time is significantly shortened. This greatly improves production efficiency, especially suitable for scenarios with high production capacity requirements.

Excellent Stability & No Platinum Black Precipitation: It has strong toxicity resistance, which can effectively resist the interference of nitrogen-containing, sulfur-containing, and other substances. This prevents the precipitation of platinum black during product storage and use, ensuring the stability of the finished product's appearance and performance.

Wide Operating Window & Easy Operation: The operating time characterized by tc10 is sufficient, reserving ample time for processes such as mixing, coating, and molding in production, and reducing operation difficulty.

Strong Environmental Adaptability: It is highly transparent with no yellowing risk. Some models comply with the standards of the FDA (U.S. Food and Drug Administration) and BfR (German Federal Institute for Risk Assessment), making them suitable for environmental requirements of high-end application scenarios such as food contact and medical care.

Excellent Thermal Stability: It can still maintain good heat resistance when used with additives, adapting to high-temperature curing scenarios of 90-200℃, and the finished product has more outstanding temperature resistance.

Part.04 | Product Performance Comparison

The curing time TC90 of the silicone system is an important indicator for measuring platinum catalysts. The relevant parameter explanations are as follows:

Vulcanization Time (Tc90): The smaller the Tc90 value, the shorter the curing time, and the higher the activity of the platinum catalyst.

Operating Time (Ts2): The longer the Ts2 time, the longer the operating time (it can also be characterized by Tc10).

Curing Degree (MH): The MH value characterizes the curing degree.

Other Related Parameters: Highest torque, lowest torque, Scorch time, etc.

Compared with similar products such as Imported A, Imported B, and Domestic A, Betely platinum catalyst shows balanced and outstanding performance in key indicators. The specific data are as follows:

| Comparison Item | Imported A | Imported B | Domestic A | Betely |

| Appearance Yellowing | OK | OK | OK | OK |

| Transparency | OK | OK | OK | OK |

| Wire Drawing Point (min) | 12 | 12 | 15 | 12 |

| Curing Time (min) | 15 | 15 | 20 | 15 |

It can be seen from the data that while maintaining the same appearance quality and curing efficiency as imported products, Betely's product has a 25% faster curing speed compared with Domestic A. This makes it more efficiently suitable for industrial production needs. In high-temperature tests (90℃ rheometer test) and room-temperature tests (wire drawing observation at 25±1℃), its curing consistency and stability are excellent, enabling stable mass production without additional process adjustments.

Part.05 | Product Application Scenarios

With its diverse product series (CSAT-F5xxxx, CSAT-F6xxxx, CSAT-F7xxxx, etc.), Betely platinum catalyst accurately meets the silicone processing needs of multiple industries:

Electronics Industry: Applied in electronic encapsulation adhesives, wire and cable silicones, and key silicones. It ensures the stability of electronic components by virtue of its excellent flame retardancy and insulation.

Daily Necessities Industry: Used in baby product silicones (e.g., pacifiers) and kitchenware silicones. It complies with food contact safety standards, featuring high transparency and anti-yellowing, and balances safety and appearance.

Medical Industry: Suitable for medical silicone tubes. It has biocompatibility and sterilization resistance, meeting the strict requirements of medical equipment.

Coating & Textile Industry: Applicable to paper release agents, PE/PET coatings, and quick labels. It has fast curing speed and uniform film formation, improving coating adhesion and durability.

Product Manufacturing Industry: Used in molded silicone products, extruded silicone profiles, and synthetic silicone oil. It has strong thermal stability and good molding effect, adapting to complex process requirements.

From core performance to industrial applications, Betely platinum catalyst takes "innovative technology" as its core, providing efficient, stable, and convenient catalytic solutions for silicone processing enterprises. For more information on specific model adaptation plans or to obtain sample tests, please contact the corporate service hotline: 18025936130, or visit the official website

www.betely.com for details!