Heat transfer silicone rubber material is a versatile material used in many applications to provide heat transfer and protection. It is a type of polymer that is used in many industries, such as automotive, aerospace, and medical, to provide insulation and protection from heat and other environmental factors. Heat transfer silicone rubber is also used to seal joints and create a safe, leak-proof environment. The silicone rubber raw material is used in many applications because it is durable and offers excellent heat transfer properties. Because of its flexibility and ability to withstand high temperatures, it is often the material of choice in many applications.

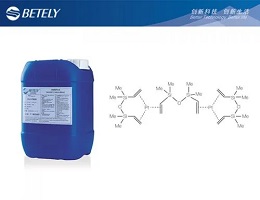

Heat transfer silicone rubber is a synthetic rubber material that is made from a combination of silicone and other materials, such as rubber, glass, carbon black, and other additives. It is then cured and formed into sheets or other shapes for use in many applications. The material has excellent heat transfer properties, making it ideal for use in heat-sensitive applications. It can also provide protection from high temperatures, ultraviolet radiation, and other environmental factors. Heat transfer silicone rubber material can be used in a variety of applications, such as automotive, aerospace, medical, and industrial applications.

Heat transfer silicone rubber material is also used in the manufacturing process of many products. It is used to seal joints, provide insulation, and help with the production of components. It is also used in the assembly of products, such as electronics, medical devices, and automotive parts. Heat transfer silicone rubber material is versatile and can be used in a variety of ways, including coating, molding, and machining.

Heat transfer silicone rubber material can be applied using several different processes. These processes include injection molding, extrusion molding, and calendaring. Injection molding is used to create complicated shapes and sizes and is often used in the production of medical and automotive parts. Extrusion molding is used to create shapes and sizes that are simpler and can be used in the production of industrial and aerospace parts. Calendaring is used to create thin sheets and thin layers of the heat transfer silicone rubber material and is often used in the production of electronics and medical devices.

Heat transfer silicone rubber material is an excellent choice for a variety of applications. It is durable, flexible, and offers excellent heat transfer properties and can be used in many industries, from automotive to aerospace and medical. Heat transfer silicone rubber material can be applied using several different processes, such as injection molding, extrusion molding, and calendaring. With its versatility and excellent heat transfer properties, heat transfer silicone rubber material is an ideal choice for many applications.