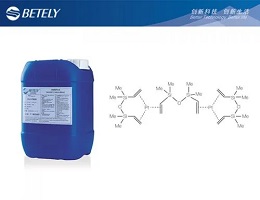

The cost-effectiveness of anti-vulcanizing agent encapsulation materials for LED is a major factor to consider when selecting the right product for your needs. BTL, a leading manufacturer of LED encapsulation materials, has developed a cost-effective solution that is designed to provide superior protection against UV light, heat, and other environmental factors. The BTL anti-vulcanizing agent encapsulation materials are engineered to be especially resistant to degradation and wear, resulting in a longer life span and improved performance for LED lighting products. Additionally, the encapsulation materials are designed to have a low thermal conductivity, reducing waste heat and providing superior protection for the LED components. The BTL encapsulation materials are also designed to be highly efficient, reducing the cost of energy consumption by up to 50%. This cost-effectiveness makes BTL's anti-vulcanizing agent encapsulation materials an ideal choice for LED lighting products.