1. Since the silver in the product will settle or jelly after being placed for a period of time, please stir it evenly before each use. It is recommended to use a blender for 1 hour before use. The screen should be clean and dry;

2. The environment is recommended for use. The temperature is controlled at 18~22℃, and the humidity is ≤60%;

3. The viscosity of the conductive silver paste has been adjusted, so do not add diluent at the beginning of use;

4. Use the silver paste within 24 hours after opening, and cut the unused silver paste Do not place it open, cover the inner and outer covers, and store it in a sealed;

5. The recycled silver paste must be stored and used separately from the normal silver paste, and cannot be mixed. To adjust the viscosity of the recycled silver paste, a special thinner XSJ-533B is required, and the addition amount does not exceed 1.5% of the total mass of the silver paste. In the long-term printing process of silver paste, if the viscosity of the paste increases, the thinner XSJ-533B can be added appropriately, and the addition amount should not exceed 1.5% of the total mass of the silver paste;

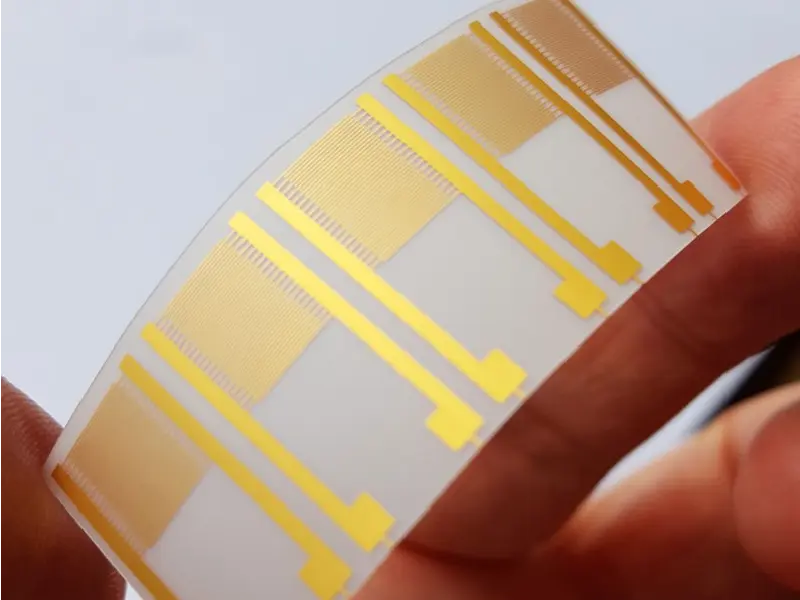

6. The substrate must be strictly dried before printing. Dust removal and static removal treatment;

7. Do not touch the substrate and silver wire parts with bare hands during operation;

8. The working environment should not contain corrosive gases such as sulfide and chloride;

9. Operators must wear masks, hats, and gloves Etc., do not use labor protection products containing sulfide;

10. Wash the skin with water and soap in the time when it comes in contact with the skin.