Silicone rubber is widely used in the coating and electronic industry for various purposes, such as adhesives, molding rubbers, and sealants. The platinum catalyst for silicone rubber ensures high-temperature resistance and thermal transfer usage. Therefore, silicone rubbers are used in heat-generating applications as well. In some cases, food-grade silicone is also made for different food products and utensils. As such, the need for a platinum catalyst for silicone rubber is on the rise.

Types of Silicone Rubber

There are four main types of silicone rubbers with different types of platinum catalyst reactions:

1. HTV

HTV or High-Temperature Vulcanizing Silicone Rubber is also called Heat Cured Silicone Rubber, which is made from reactive gums of silicone. Such a unique production method can enhance the mechanical properties of the rubber and make it heat-stabilized. The organic peroxides are cross-linked, which makes the system more stable. The High Consistency Rubber is available in a solid state and can withhold high temperatures in the same solid conditions.

2. LSR

LSR is the liquid version of HTV. It is Liquid Type-High Temperature Vulcanization Silicone Rubber. Here, the main difference from Millable Type Silicone Rubber is the high degree of viscosity and curing temperatures of the LSR. It can be used in demanding designs that require high tolerance and complex molds as it can easily fill the complex mold parts.

3.RTV-2

RTV-2 are basically room temperature silicone rubber vulcanization with two components. Each component acts as a crosslinker for the rubber. Therefore, the degree of viscosity can be varied as per client requirements. This type is also resistant to chemical and thermal damage.

4. RTV-1

Much like the RTV-2, the main difference RTV-1 has is its single-component design. It is easier to use but may not work well in complex usage.

Platinum Catalyst Usage on Silicone Rubber Curing

The platinum catalyst reaction method is a prime way of silicone rubber curing. Are you wondering how platinum catalysts work? The catalyst faces the processes of liquid addition to silicone rubber, synthesis of silicone oil, and as a paper separator. The process requires oxygen to accelerate its speed. Additionally, organic peroxides are also a crucial factor in the bonding process.

7 Key Factors of Filling a Prescription of Platinum Catalyst

The platinum catalyst for silicone rubber focuses on seven major aspects.

1. Hardness

The hardness of the silicone rubber must be considered to determine the right amount and type of platinum catalyst required.

2. Strength

The strength and durability of the platinum catalyst for silicone rubber are another important consideration when filling the prospection. Lower amounts of the platinum catalyst for silicone rubber are required if the system’s strength is minimal.

3. Consistency

The prescription of the platinum catalyst for silicone rubber must be consistent. Otherwise, the usage may result in inconsistent results.

4. Time of Cure

The longer the cure time, the greater the platinum catalyst for silicone rubber prescription is required. Using lower quantities may result in items giving up mid-process.

5. Work Time

The work time of the platinum catalyst for silicone rubber is varied based on the prescription prepared. For greater work time, more quantities are required.

6. Shelf Life

The platinum catalyst for silicone rubber may be required in higher quantities if the silicone rubber is required to stay on the shelf for a longer time.

7. Compounding

The compounding components, including the peroxides and the amount of oxygen available, are crucial determinant factors for the prescription of platinum catalyst for silicone rubber.

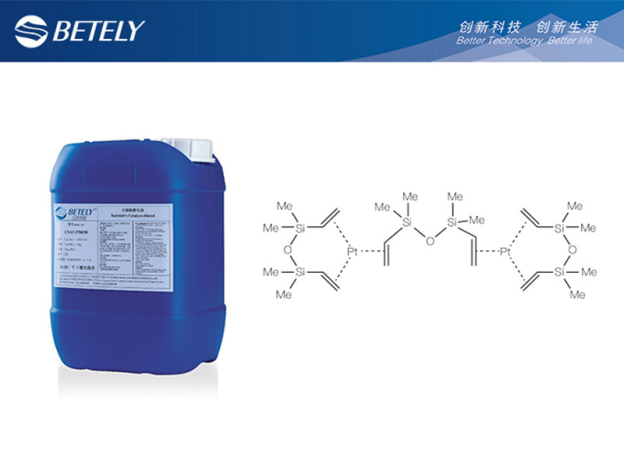

As one of the top platinum catalyst suppliers, Betely brings you the best Silicone Rubber products. BTL platinum catalysts for silicone rubber are highly effective, durable, and cost-effective. Using our platinum catalyst for silicone rubbers can produce all types of silicone required for industrial purposes. Similarly, we are certified for our product’s quality and production methods. Many large-scale and global firms partner with us for the silicone rubbers required for their products. Don’t miss the opportunity!

Contact us now at https://www.betelychina.com/.