The textile industry has long faced challenges related to energy consumption, chemical usage, and wastewater management. Innovations in catalytic chemistry have opened new avenues for sustainable production, and platinum catalysts have emerged as one of the most effective solutions. These catalysts enhance chemical reactions while minimizing environmental impact, offering benefits that are transforming textile processing worldwide.

Betely, a trusted leader among platinum catalyst suppliers, leverages advanced technologies to provide high-quality catalysts. By incorporating Betely's solutions, manufacturers can reduce waste, lower emissions, and achieve higher process efficiency.

When evaluating the cost of platinum catalyst, buyers should consider both the initial investment and long-term performance benefits. This blog explores the environmental benefits of platinum catalysts in textile processing, highlighting their applications, advantages, and why partnering with reputable suppliers is crucial.

What Is a Platinum Catalyst and How Does It Support Sustainable Textile Processing

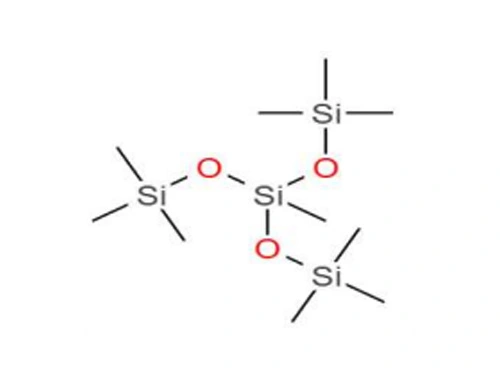

A platinum catalyst is a chemical substance that accelerates reactions without being consumed in the process. In textile manufacturing, platinum catalysts are primarily used in oxidation, hydrogenation, and other chemical reactions critical to dyeing, finishing, and fabric treatment.

The environmental benefits arise because these catalysts:

Reduce the need for excess chemicals in reactions

Lower energy consumption by enabling reactions at milder temperatures

Minimize byproducts and hazardous waste

Using a platinum catalyst ensures that processes such as bleaching, dye fixation, and fiber modification can be performed more efficiently, reducing both resource use and environmental impact.

Key Platinum Catalyst Uses in the Textile Industry

Textile processing involves several steps where platinum catalysts can improve environmental performance:

A. Dyeing and Color Fixation

Platinum catalysts accelerate oxidation reactions, allowing dyes to bind more efficiently to fibers.

This reduces the quantity of dyes and auxiliary chemicals required, lowering chemical discharge into wastewater.

B. Bleaching and Whitening

Catalysts facilitate oxidative bleaching at lower temperatures.

Reduced energy usage translates directly to lower carbon emissions.

C. Finishing and Fiber Modification

Platinum catalysts enable environmentally friendly finishing reactions, such as hydrophilic or flame-retardant treatments.

These reactions require fewer harsh chemicals, producing safer effluents.

By integrating platinum catalyst uses across these processes, textile manufacturers can align production with sustainability goals and regulatory standards.

Environmental Advantages of Using Platinum Catalysts

The adoption of platinum catalysts in textile processing provides tangible ecological benefits:

A. Reduced Chemical Consumption

Reactions proceed more efficiently, requiring lower quantities of dyes, oxidizers, and finishing agents.

B. Lower Energy Requirements

Many catalytic reactions occur at moderate temperatures, saving energy compared to traditional methods.

C. Minimized Wastewater Pollution

Efficient reactions lead to fewer byproducts, which reduces pollutant load in wastewater streams.

D. Support for Green Manufacturing

Platinum catalysts facilitate cleaner production techniques, helping textile companies meet sustainability certifications and environmental regulations.

Betely, among the top platinum catalyst suppliers, ensures that their products maximize these environmental advantages while maintaining process efficiency.

Choosing the Right Platinum Catalyst Suppliers

Selecting a reliable platinum catalyst supplier is essential to ensure performance, consistency, and sustainability. Key considerations include:

Quality Assurance: Ensure catalysts meet industrial standards for activity, stability, and purity.

Support and Consultation: Experienced suppliers offer guidance on process optimization and environmental impact reduction.

Supply Reliability: Continuous production requires steady access to high-quality catalysts.

Partnering with a trusted supplier ensures manufacturers can leverage platinum catalyst uses effectively while maintaining environmental compliance and operational efficiency.

Conclusion

Platinum catalysts play a crucial role in advancing environmentally sustainable textile processing. Their ability to reduce chemical consumption, lower energy usage, and minimize wastewater pollution makes them an indispensable tool for modern textile manufacturers. By sourcing catalysts from reputable platinum catalyst suppliers like Betely, businesses can achieve both ecological and operational benefits.

Investing in high-quality catalysts not only improves production efficiency but also strengthens a company's commitment to green manufacturing—a vital consideration for today's environmentally conscious market.