In the wire and cable industry, where safety, flexibility, and heat resistance are critical, silicone rubber has become a material of choice. To achieve optimal performance in silicone rubber formulations, especially in addition-curing systems, the role of a high-quality platinum catalyst is indispensable. Among the leading platinum catalyst suppliers, Betely delivers high-performance solutions with its advanced BTL platinum catalyst series, offering unmatched efficiency, stability, and adaptability.

Why Platinum Catalysts Are Essential in Silicone Rubber for Wire & Cable

Silicone rubber used in wire and cable sheathing and insulation must meet stringent demands—heat resistance, flame retardancy, flexibility, and long-term stability. These performance metrics depend heavily on the curing system, particularly the platinum catalyst that drives the cross-linking reaction.

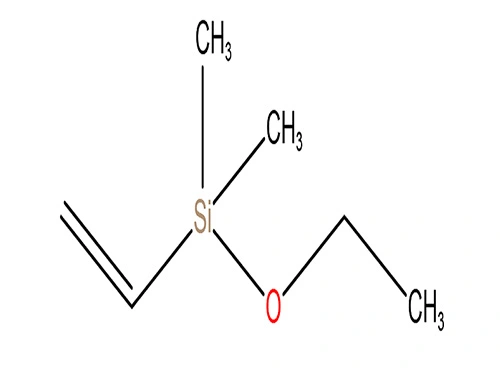

Platinum catalysts are primarily used to catalyze addition reactions between vinyl-functional (Si-Vi) and hydride-functional (Si-H) silicone polymers. Betely's platinum catalyst offers high catalytic activity with no side reactions, ensuring complete and controlled cross-linking. This results in a finished product with excellent mechanical properties and thermal resistance, critical for high-voltage and flame-retardant wire insulation.

Key Features of Betely's Platinum Catalyst in Silicone Rubber

Feature Benefit

High Catalytic Activity Enables rapid and complete cross-linking between Si-Vi and Si-H groups

Fast Curing Time (with 4H₂) Speeds up production cycles without sacrificing quality

Excellent Thermal Resistance Withstands high temperatures and thermal cycling in cable environments

High Toxic Resistance Remains effective even in the presence of amines, phosphines, sulfur

Low Color & Turbidity Maintains optical clarity in transparent or colored cable compounds

Fire Resistance Supports flame-retardant formulations for safety-critical applications

Stable Platinum Formulation Long shelf life and consistent batch-to-batch performance

Why Choose Betely as Your Platinum Catalyst Supplier

As a global player among platinum catalyst suppliers, Betely brings innovation and reliability to the table. Their BTL platinum catalyst products—including the PTO2 catalyst—are engineered with a stable platinum formulation that combines platinum, palladium, and/or rhodium, offering high selectivity and efficiency across multiple industrial reactions.

Conclusion: Smart Curing for Smarter Cables

From insulation to flame-retardant sheathing, silicone rubber treated with Betely's platinum catalyst ensures superior durability, clarity, thermal endurance, and safety. For manufacturers looking to boost efficiency while maintaining high-quality standards, Betely remains a trusted partner in the field of platinum catalyst uses.

By choosing Betely, you're choosing innovation, consistency, and performance in one package—making it a smart decision for any wire and cable silicone rubber application.