Due to the rapidly changing technology, material performance becomes excessively critical these days, especially in medical devices where human lives are at stake. The challenge for medical materials is that they have to be tough enough to withstand challenges like temperature, pressure, etc. while being soft enough not to be harsh on the patient. Due to this reason, the importance of silicone rubber material has increased in manifolds in the latest medical devices.

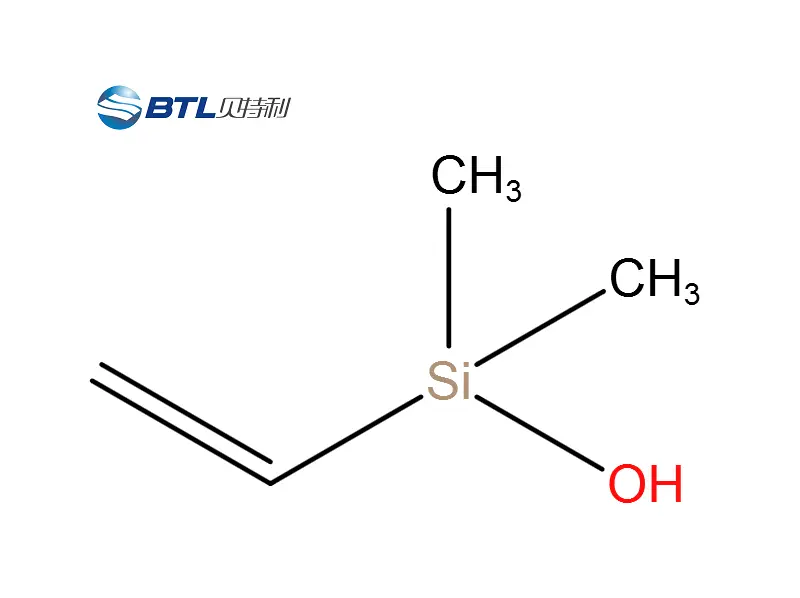

The silicone rubber material is a silicon-made elastomer (rubber-like material) combined with other elements like vinyl, hydrogen, and other additives. Their properties make them suitable for a wide range of applications in medical materials, including the following domains.

The Applications of medical-grade silicone rubber in medical devices

Infusion Pump

An infusion pump is a device that is used to infuse nutrients into your body. The traditional material used in these devices can be dangerous when it comes in contact with the human body, resulting in a number of diseases. However, with silicone rubber material infusion tubes, a patient can be injected the required nutrient and fluid in his body with safety insurance.

Negative Pressure Ball

Medical suction machines have proven their benefits over a long period of time. In order to clear the airways along with many other lethal functionalities, this machine is used. However, the material of this machine should be resistant to all the chemical reactions after touching the body. The silicone rubber material is a perfect solution to use in these negative pressure balls to avoid danger.

Menstrual Cup

The use of silicone rubber material has also increased manifold in menstrual cup materials. Considering the sensitivity of its usage, the material of the menstrual cup must be made of a non-reactant substance. Apart from these, silicone rubber is also used in a wide variety of medical equipment, such as catheter devices and throat-related devices.

The Advantages of medical silicone rubber in medical devices

Flexibility

The usage of medical-grade silicone rubber material provides extreme flexibility in making medical equipment. LSR can be molded into different shapes without being trapped within the mound. Using liquid silicone rubber material, multiple parts like a lens or protective cover can be combined into one part, thereby reducing the cost.

Transparency

Optical LSR is highly transparent. It is more transparent than any other plastic available in the medical industry. What is more, the stability of optically clear liquid silicone rubber resists it from getting damaged due to heat from light sources, resulting in increased equipment lifetime.

Resistance Power

As medical devices that touch human body parts, the medical devices’ material must be resistant to acids, bases, pressure, and extreme temperature environments. Medical-grade silicone rubber material provides resistance in all those environments without any adverse effect on the human body.

Economical

Because of their reliability, medical-grade silicone rubber materials are highly versatile and can remain functioning over an extended period of time. Its components are neither flammable nor dangerous, so you don’t have to take external safety measures. The medical-grade silicone rubber device can function in extreme temperature conditions and is therefore applicable in a range of circumstances. All this helps in cost reduction.

Betely is a professional silicone rubber manufacturer that provides you with the degree of caution that you have to observe while using these medical devices. By using Betely’s equipment made up of silicone rubber material, safety is guaranteed, and you can immune yourself from all the diseases spread through traditional medical devices. Manufactured with great care under-qualified doctors and nursing staff, Betely provides products that comply with internationally accepted standards.