Medical science continues to evolve with new materials and manufacturing techniques that ensure safer, more effective, and more reliable healthcare solutions. Among these innovations, liquid silicone rubber (LSR) has emerged as a cornerstone in modern medical technology. Known for its versatility and exceptional biocompatibility, LSR injection molding is reshaping how we design and produce medical devices and implantable solutions. Companies like Betely are at the forefront of driving this transformation, offering advanced formulations of medical silicone material that meet the highest global standards.

Understanding LSR Injection Molding

LSR injection molding is a specialized process that involves the mixing and curing of two-component liquid silicone at high temperatures inside precision molds. Unlike traditional silicone rubber processing methods, LSR injection molding allows for automated, high-volume production of complex, intricate parts with exceptional accuracy.

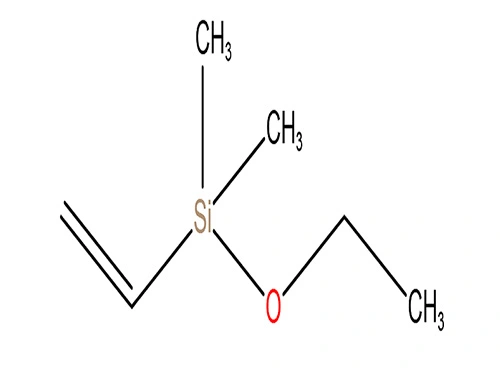

The process begins with two liquid components—typically a base polymer and a curing agent—being combined and injected into a heated mold cavity. The heat triggers rapid curing, producing durable and flexible medical-grade components. This method is particularly valuable for manufacturing parts with tight tolerances, thin walls, or complex geometries, making it an indispensable technology for silicone rubber in medical applications.

For medical manufacturers, LSR injection molding offers several advantages:

Consistency: Automated processes reduce defects and ensure uniform quality.

Precision: Ideal for small and complex devices, such as microfluidic components or intricate implant structures.

Scalability: Capable of producing millions of identical units efficiently.

Advantages of Medical Silicone Rubber

The widespread adoption of medical silicone rubber in healthcare is due to its outstanding material properties. Unlike many plastics or elastomers, medical silicone is highly biocompatible, ensuring that it can remain in contact with human tissues and fluids without causing irritation, inflammation, or toxic reactions.

Some key advantages include:

Durability and flexibility: LSR maintains its properties across a wide temperature range, making it suitable for both external devices and long-term implants.

Non-reactive and stable: It does not degrade when exposed to sterilization methods such as autoclaving, radiation, or chemical disinfection.

Patient comfort: Its softness and flexibility make it ideal for wearable healthcare products and implantable devices that must integrate seamlessly with the human body.

Because of these qualities, medical silicone material is used in syringes, catheters, surgical instruments, artificial heart valves, prosthetic limbs, and even contact lenses. Its unique balance of safety and performance makes it the preferred choice over alternative polymers.

Applications in Medical Devices and Implants

The role of silicone rubber in medical applications extends far beyond simple tubing or seals. Today, LSR is integral to the production of life-saving and life-enhancing technologies.

Wearable health technologies: LSR is used for comfortable, skin-friendly components in fitness trackers, medical sensors, and therapeutic patches.

Critical medical tools: Catheters, respiratory masks, and surgical seals benefit from LSR's ability to withstand sterilization without compromising flexibility.

Prosthetics and orthopedics: Soft, durable silicone components improve the comfort and functionality of prosthetic limbs and orthopedic supports.

By enabling both disposable and long-term use products, LSR continues to push boundaries in medical design, ensuring better patient outcomes and enhancing the reliability of healthcare devices worldwide.

Betely and the Future of Medical Silicone Material

As the medical industry expands, demand for certified and reliable silicone solutions continues to grow. Betely has positioned itself as a trusted partner in this space, offering medical silicone for sale that complies with rigorous safety and quality standards. By leveraging cutting-edge LSR injection molding technologies, Betely supplies materials that not only meet but exceed the expectations of global healthcare manufacturers.

Looking forward, innovations such as bioresorbable silicone, smart materials with drug-delivery capabilities, and advanced surface modifications will further elevate the role of silicone in medicine. With pioneers like Betely leading the charge, the future of medical silicone material promises safer, smarter, and more personalized healthcare solutions.