When a blood glucose meter displays a number, what truly determines its accuracy is often hidden deep inside the test strip—materials you never see: conductive pastes and insulating inks.

At Betely, we are specialists in these critical core materials.

For more than 20 years, we have deliberately stayed away from finished medical devices, focusing instead on what matters most at the foundation level—building a stable signal system and a reliable reaction safety zone for blood glucose test strips. From the very start, we safeguard the accuracy of every measurement through materials science.

From Blood to Data: Materials as the Invisible Key Driver

1. Blood Sampling

A small blood sample is collected using a lancet.

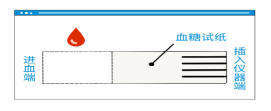

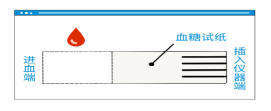

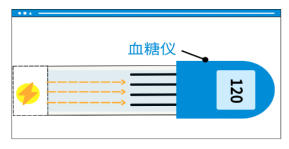

2. Blood Glucose Test Strip

The strip includes a blood inlet end and a meter insertion end.

3. Blood Enters the “Reaction Boundary”

The blood flows into a precisely defined reaction area formed by insulating ink.

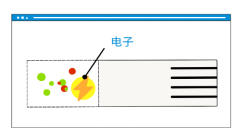

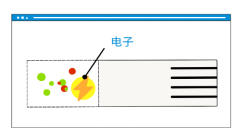

4. Glucose Reaction Occurs

Glucose reacts with enzymes, releasing electrons and generating a micro-current.

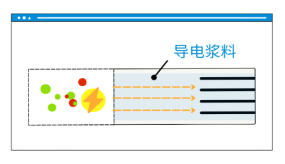

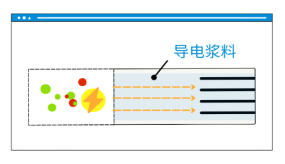

5. Signal Capture by Conductive Paste

Electrodes made with conductive silver paste or carbon paste accurately capture this micro-current and transmit it to the processor.

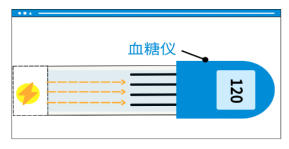

6. Result Displayed on the Meter

The glucose meter receives the signal, calculates the concentration, and displays the result on screen.

Behind this seemingly simple process lies a highly controlled materials system that determines whether the data can truly be trusted.

The Safety Zone: Betely Insulating Ink — the Solid Isolation Wall of Blood Glucose Test Strips

In enzyme-based reaction zones, Betely insulating ink acts as a precise “wall,” firmly fixing the reaction region in place.

Like a carefully drawn boundary, it ensures that enzyme–blood reactions stay exactly where they should—no deviation, no overflow.

Resistant to common contaminants such as alcohol residue and sweat, effectively shielding the reaction from external interference and preserving data authenticity.

Clean printing edges, excellent abrasion resistance, and long-term stability ensure consistent performance throughout the product lifecycle.

The Signal System: Betely Conductive Silver Paste & Carbon Paste — The Sensitive Nerve Lines of Blood Glucose Test Strips

Comparable to a noise-free radio signal, Betely conductive pastes deliver high signal fidelity with minimal deviation, achieving low CV values within ideal ranges.

Designed not to interfere with the enzymatic reaction between glucose and enzymes, ensuring pure and accurate detection.

Fast drying, strong adhesion, and excellent scratch resistance improve manufacturing yield and ensure smoother, more efficient production processes.

Core Materials from Betely

Insulating Ink

Conductive Silver Paste

Conductive Carbon Paste

All engineered to meet the stringent requirements of blood glucose test strip manufacturing.

Choose Betely — Three Core Advantages for Your Product

1. Enhanced Product Performance

High material consistency and stability reduce measurement error at the physical level, creating clear differentiation in your glucose monitoring products.

2. Optimized Manufacturing Efficiency

Excellent process compatibility and wide tolerance margins help improve production yield and effectively control total manufacturing costs.

3. Stronger Brand Trust

By ensuring anti-interference capability and long-term stability from the source, Betely materials help build lasting trust in your brand and your products.

For more than two decades, we have proudly remained an “invisible champion.”

Behind every reliable and precise blood glucose reading, Betely materials are quietly doing their job.

We warmly invite partners across the medical industry to connect and collaborate.

With materials innovation as our wings, let us jointly build stronger safeguards for health and create medical products that users can truly trust.