Classification of Silicone Rubber

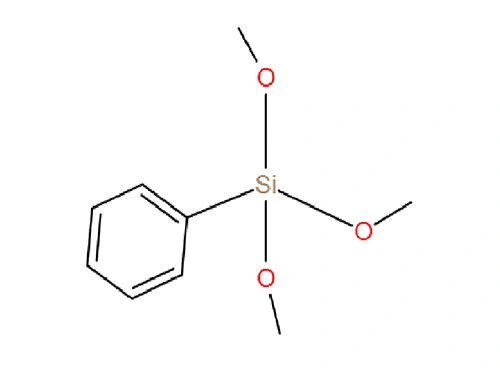

Silicone rubber is a kind of network structure elastomer crosslinked by linear polysiloxane with high molecular weight divided into solid silicone rubber and liquid silicone rubber.

Solid Silicone Rubber

Composition: High molecular weight silicone polymer + filler

Shape: Solid

Usage: Add sulfurizing agents (such as platinum catalysts) for molding or extrusion.

Liquid Silicone Rubber

Composition: Polysiloxane + filler

Shape: Liquid or paste

Usage: A / b two-component mixed molding

Note: Self-adhesive liquid adhesive belongs to this kind of particular branch.

Manufacturing Process of Silicone Rubber

1. Solid Molding

Solid molding is mainly suitable for solid glue and liquid glue (only for back-section molding). The structure of the product is simple. As an essential production process of silicone rubber, solid molding can be divided into the following five steps:

Material preparation (solid rubber)

⇓

Mixed refining (solid rubber + curing agent

or other additives, color paste)

⇓

Sheet Cutting (set size)

⇓

Molding (vulcanizing in mold)

⇓

Edge Removal

⇓

Other Processes (printing or other processes +

secondary vulcanization + inspection/packaging, etc.)

2. Solid Extrusion

Solid extrusion is mainly applied to solid silicone rubber, with a simple structure, high efficiency, and continuous production rate. As an essential production process of silicone rubber, solid molding can be divided into the following five steps:

Material preparation (solid rubber)

⇓

Mixing and Opening (solid rubber + curing agent or other additives, color paste)

⇓

Feed Extrusion (built-in mold)

⇓

Baking Molding (put into a mold for vulcanization)

⇓

Packaging (printing or other processes + secondary vulcanization + inspection/packaging, etc.)

Because liquid rubber silicone molding is complex, we will discuss the critical components of the liquid injection process in detail.

Critical Components of the Liquid Injection Process

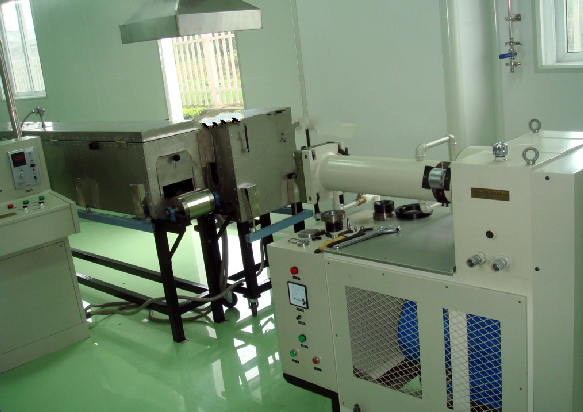

LIMS has the unique advantage of forming under low pressure, so it is necessary to set the pressure and injection speed.

Use the pressure pump to accurately measure liquid A and liquid B in a particular proportion (1:1), and then press out the two liquids simultaneously.

The raw materials of liquid A and liquid B in the portable tank (or bucket tank) are pumped.

The two kinds of liquid are thoroughly mixed by dynamic stirring or static stirrer and injected directly into the mold under pressure.

Because the nozzle has valve control, there is no problem with raw material leaking from the nozzle.

With the linkage of the feeding device, metering pump, an injection device, the mold is locked and opened.