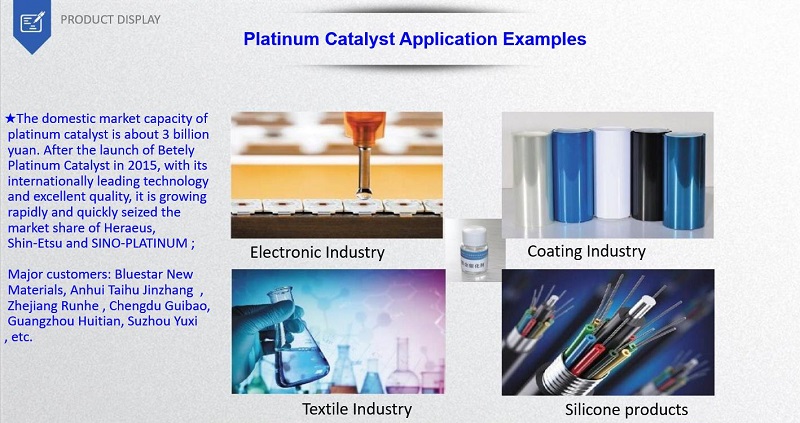

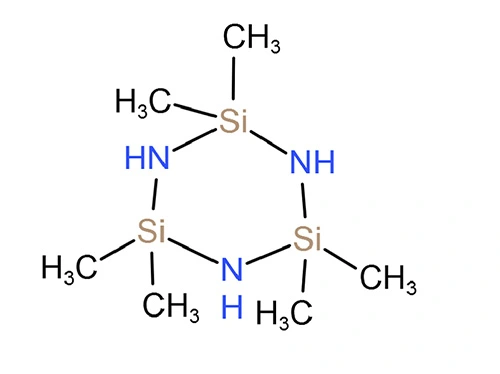

With the development of technology and the growing demand for high-performance materials, platinum catalysts have become an essential core technology in high-end extruded silicone products. Since the launch of Betely Platinum Catalyst in 2015, it has quickly emerged as a market leader with its superior performance and high stability, rapidly seizing market share from well-known brands like Heraeus, Shin-Etsu, and SINO-PLATINUM. So, why are more and more high-end silicone products choosing platinum catalysts? In the following, we will delve into the advantages of platinum catalysts in high-end silicone manufacturing.

High Transparency: Enhancing Product Appearance and Quality

High transparency is a fundamental requirement for many high-end silicone products, especially in industries like consumer electronics, medical, and baby products. Silicone products made using Betely platinum catalysts achieve excellent clarity, making the surface smoother and clearer. Platinum catalysts not only improve the transparency of silicone but also ensure that the material maintains stable color during the processing, preventing yellowing or other undesirable phenomena. This ensures that the silicone products meet the highest visual standards and provide a better experience for consumers.

Additionally, platinum catalysts effectively suppress pigment precipitation and oxidation, allowing silicone products to maintain high transparency over long periods of use and storage. This is especially critical for applications where aesthetic qualities are paramount. Being a solutions-focused silicone supplier, we've perfected the balance between technical excellence and visual perfection.

Excellent Heat Resistance and Good Compatibility with Additives

Platinum catalysts are known for their excellent heat resistance, and they can incorporate a variety of additives into the silicone without negatively affecting its performance. This makes platinum-catalyzed silicone products highly stable even in high-temperature environments. For applications such as cables, electronic packaging, and other high-temperature scenarios, platinum catalysts offer superior protection, ensuring that the silicone remains stable and functional without deformation, aging, or loss of properties.

Platinum catalysts also interact well with different additives, enhancing the overall performance of silicone, such as flame retardancy, UV resistance, and more. Through the use of platinum catalysts, silicone not only maintains its basic physical properties but also meets the specific requirements of various industries, giving it a competitive edge in the market.

Faster Curing Time: Boosting Production Efficiency

Production efficiency is a crucial factor for many manufacturers. Faster curing is one of the standout features of platinum catalysts, which significantly shortens the curing time of silicone products. In traditional silicone production processes, longer curing times often slow down the manufacturing efficiency. However, platinum catalysts optimize the curing reaction, allowing silicone to crosslink and cure in a shorter amount of time.

This feature is especially important for high-volume and high-efficiency manufacturing processes, such as extruded silicone product production. It effectively increases the throughput of production lines, reducing the production cycle. Additionally, the faster curing technology helps lower energy consumption during production, saving costs and improving profitability for businesses.

Strong Fire Resistance and High Flash Point: Ensuring Safety

In many high-end silicone applications, safety is a key consideration. Betely platinum catalysts provide exceptional fire resistance and a high flash point (>100°C), making them a notable advantage. Platinum catalysts improve the fire resistance of silicone, enabling it to remain stable in high temperatures or fire-prone environments, without catching fire or degrading under heat.

This property is crucial for applications such as cables, electronic device housings, and medical equipment, where products are often exposed to high temperatures, fires, or electrical faults. Silicone made with platinum catalysts significantly reduces the risk of fire and provides higher safety in the event of a fire, meeting the stringent safety standards required by various high-end markets.

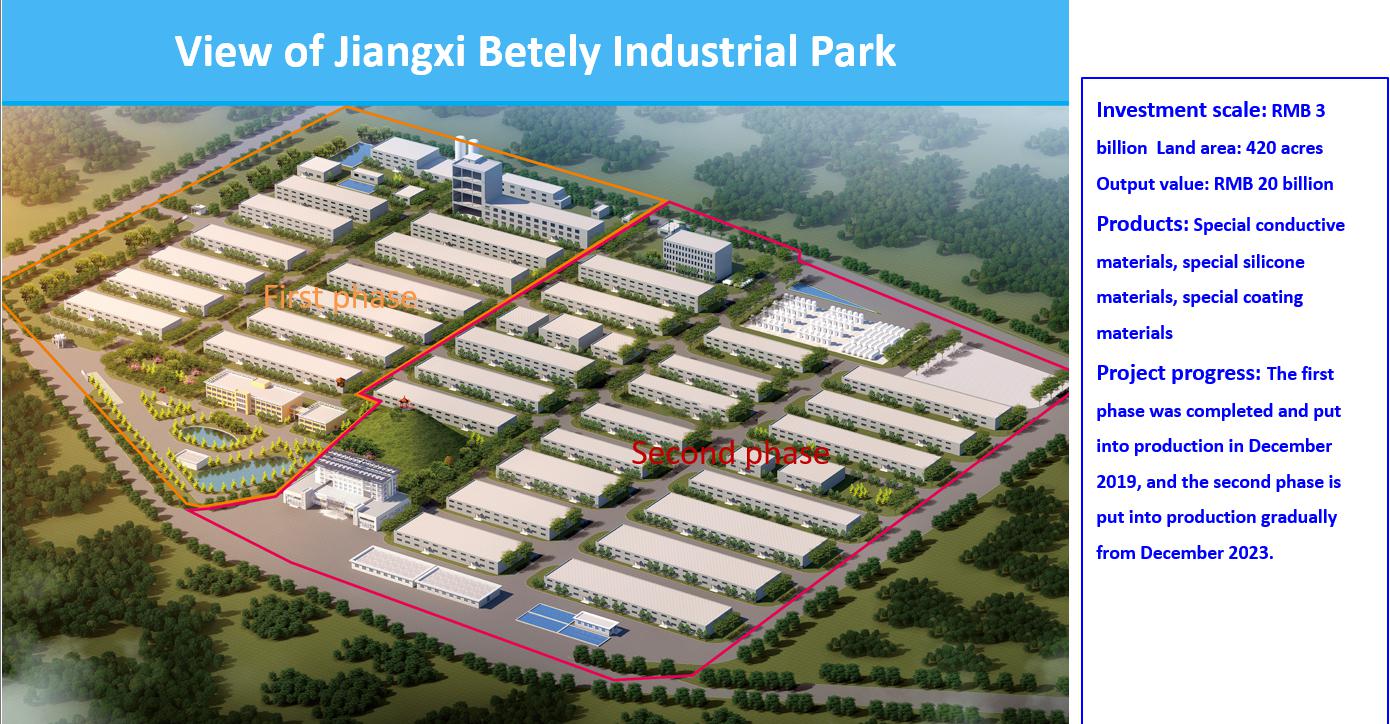

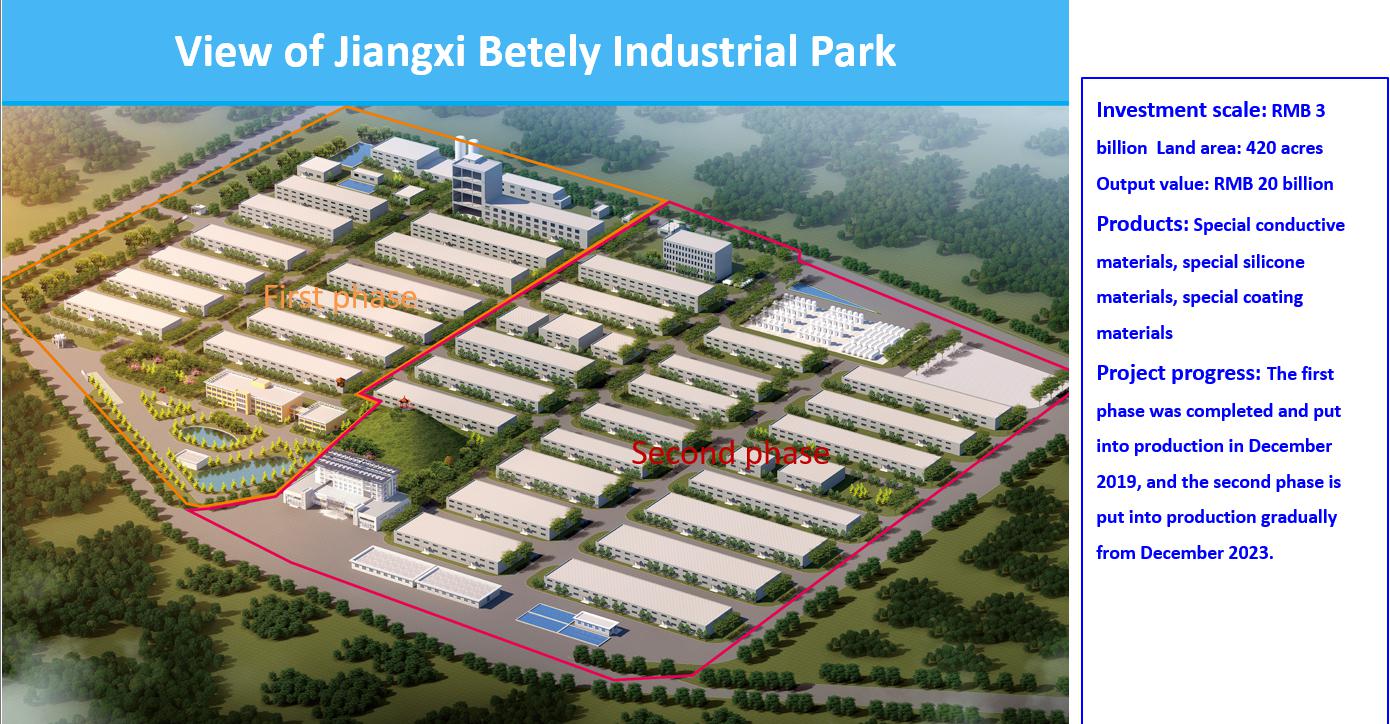

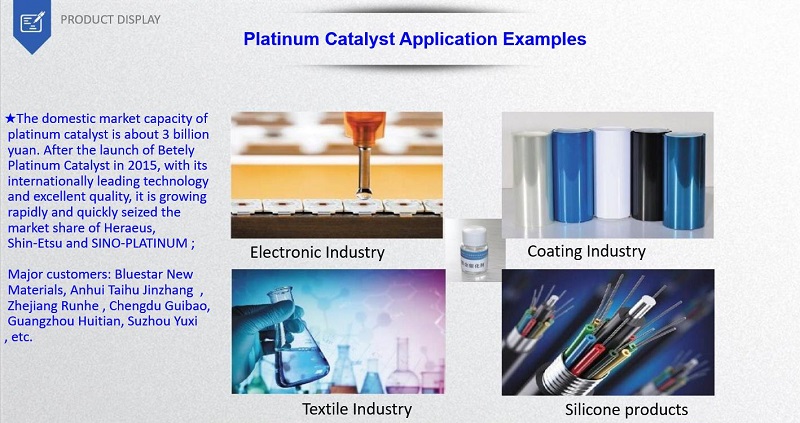

Betely Platinum Catalyst's Industry Impact and Market Share

Since the launch of Betely Platinum Catalyst in 2015, it has quickly gained market share due to its world-leading technology and excellent product quality. By offering efficient catalytic reactions, outstanding heat resistance, and rapid curing times, Betely platinum catalysts have become highly favored by global manufacturers.

In a highly competitive market, Betely, one of the top platinum catalyst suppliers in the market, has expanded its applications and become an industry leader with its technological edge. Compared to traditional brands like Heraeus, Shin-Etsu, and SINO-PLATINUM, Betely's advantages in innovation and product quality have not only led to rapid market recognition but also pushed the industry towards technological progress.

High-end extruded silicone products are widely used in various industries, including electronics, cables, medical devices, and more. Platinum catalysts have undoubtedly become a key factor in enhancing the performance and production efficiency of silicone products. From high transparency and heat resistance to faster curing times and strong fire resistance, Betely Platinum Catalyst has become one of the most popular choices in the market. With its world-leading technology and high-quality standards, Betely is continuously reshaping the high-end silicone industry and driving it towards new heights.

Whether manufacturers are looking to improve production efficiency, enhance product safety, or elevate overall performance, Betely Platinum Catalyst is undoubtedly the ideal choice for high-end silicone manufacturing.