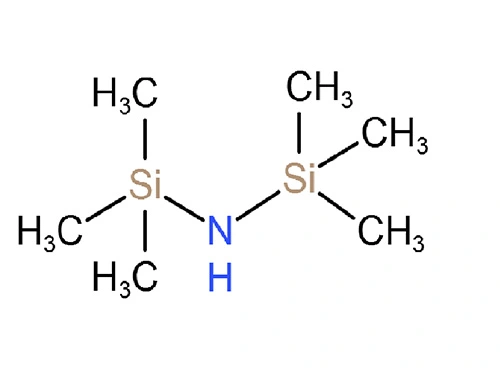

As we all know, the manufacturing of silicone medical devices is a multi-step process that requires thorough attention to detail to ensure the product is safe to use for patients. It is crucial to have quality control measures in place to guarantee the accuracy and safety of every aspect of the manufacturing process from beginning to end. This is where medical silicone material comes into play.

Medical silicone material is a key component in the manufacture of high-quality and safe medical devices. The use of high-quality silicone material ensures that the end product will withstand the pressure and stress it will be subjected to in its intended application.

Quality control is so important in the manufacturing of silicone medical devices because patients are relying on these products to help improve their health and quality of life. Any defect or compromise in the device's functionality could have negative and even life-threatening consequences. With this in mind, let's dive into why quality control is essential in the manufacturing of silicone medical devices.

Ensuring Uniformity of Medical Silicone Material

One of the most important aspects of quality control in the manufacturing of silicone medical devices is ensuring that the medical silicone material used is uniform. Consistency in material quality is crucial to ensuring that leakage, ruptures, and other issues don't arise down the line. All medical silicone materials should undergo strict quality control measures to ensure they meet specific performance requirements.

Maintaining Quality Standards Throughout the Manufacturing Process

Quality control measures should be implemented at every stage of the manufacturing process to ensure that the entire device meets the required standards. Every batch of medical silicone material used should be tested to assure the quality of the final product. This includes ensuring that the manufacturing process follows standard procedures, and that only high-quality products are used.

Testing the Finished Product

Lastly, quality control measures should include testing the finished product to ensure its safety and effectiveness. The manufacturer should test every device for any defects it may have. Furthermore, medical silicone material should be tested to ensure the device will be safe and effective in the intended medical application.

In conclusion, quality control plays a crucial role in the manufacturing of silicone medical devices. High-quality medical silicone material is essential to ensure that the device will operate correctly and serve its intended purpose without presenting any risk to patients. For this reason, patients' safety should be at the forefront of the manufacturing process. Quality control measures help to ensure that the manufacturer meets all expected requirements and produce quality products that protect the patients.